-

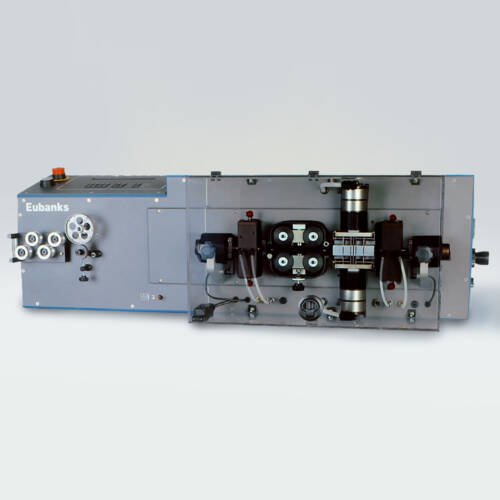

The 2940 is the largest and most powerful cable stripper Eubanks manufactures. It is equipped with a powerful cutter head that generates up to 1,800 P.S.I. (12,000 kPa). It is designed specifically for processing hard-to-strip large battery cables. Equipped with the standard tooling, the 2940 can cut and strip single-stranded conductor wires ranging from 10 to 2AWG (5.3mm2 up to 33.6mm2), with a maximum O.D. of 480” (12.1mm). Now with extended capacity using optional tooling and modification kits, the 2940 can process wires down to 18 AWG (0.96 mm2) and up to 2/00 AWG also known as 2 Ott, with a maximum O.D. of .625” (15.8mm). The 2940 can also process a wide variety of cable types such as round or flat multi-conductor cables, parallel conductor cables with 2, 3, or 4 conductors, and coaxial cables. Wire Length is not a problem it can process wire lengths from 3 in. to 8,333 feet (101.6mm to 2,540m) basically a mile and a half. The 2940 cuts and strips both ends of the wire or cable in a single cycle. It strips perfectly square ideal for termination. The 2940’s production screen can display an estimate of pieces per hour being produced at the current feed speed. The production screen also displays an estimated time of completion. Download the Eubanks Engineering AirStrip 2940 specifications for more detailed information. New Customers: Click here for information on ordering blades and blocks. Existing Customers: Click here for information on order blades. Existing Customers: Click here for information on order blocks.

The 2940 is the largest and most powerful cable stripper Eubanks manufactures. It is equipped with a powerful cutter head that generates up to 1,800 P.S.I. (12,000 kPa). It is designed specifically for processing hard-to-strip large battery cables. Equipped with the standard tooling, the 2940 can cut and strip single-stranded conductor wires ranging from 10 to 2AWG (5.3mm2 up to 33.6mm2), with a maximum O.D. of 480” (12.1mm). Now with extended capacity using optional tooling and modification kits, the 2940 can process wires down to 18 AWG (0.96 mm2) and up to 2/00 AWG also known as 2 Ott, with a maximum O.D. of .625” (15.8mm). The 2940 can also process a wide variety of cable types such as round or flat multi-conductor cables, parallel conductor cables with 2, 3, or 4 conductors, and coaxial cables. Wire Length is not a problem it can process wire lengths from 3 in. to 8,333 feet (101.6mm to 2,540m) basically a mile and a half. The 2940 cuts and strips both ends of the wire or cable in a single cycle. It strips perfectly square ideal for termination. The 2940’s production screen can display an estimate of pieces per hour being produced at the current feed speed. The production screen also displays an estimated time of completion. Download the Eubanks Engineering AirStrip 2940 specifications for more detailed information. New Customers: Click here for information on ordering blades and blocks. Existing Customers: Click here for information on order blades. Existing Customers: Click here for information on order blocks. -

Our flagship pneumatic stripper, the 2700, is a high-speed machine that can handle almost anything you can throw at it. Equipped with the standard tooling, the 2700 can cut and strip solid and stranded conductor wires ranging from 22 AWG (0.38mm2) up to 10 AWG (5.3mm2). With optional tooling and modification kits, it can process wires from 32 (0.03 mm2) to 8 AWG (8.6mm2), with a max. O.D. of .290 in. (7.4mm). The 2700 can also process a wide variety of cable types such as round or flat multi-conductor cable, parallel conductor cable with 2, 3, or 4 conductors, can strip coaxial cable in 2 stages, and cut and strip fiber optic cables made of plastic or glass and even with Kevlar reinforced fibers. It’s so flexible that it can precisely strip and slit 2 and 3 parallel conductor wires. With special setups, it can do an offset strip on 2 parallel conductor wires. Wire lengths are not a problem it will measure and cut lengths up to 99,999,99 inches, basically a mile and a half. Download the Eubanks Engineering AirStrip 2700 specifications for more detailed information. New Customers: Click here for information on ordering blades and blocks. Existing Customers: Click here for information on order blades. Existing Customers: Click here for information on order blocks.

Our flagship pneumatic stripper, the 2700, is a high-speed machine that can handle almost anything you can throw at it. Equipped with the standard tooling, the 2700 can cut and strip solid and stranded conductor wires ranging from 22 AWG (0.38mm2) up to 10 AWG (5.3mm2). With optional tooling and modification kits, it can process wires from 32 (0.03 mm2) to 8 AWG (8.6mm2), with a max. O.D. of .290 in. (7.4mm). The 2700 can also process a wide variety of cable types such as round or flat multi-conductor cable, parallel conductor cable with 2, 3, or 4 conductors, can strip coaxial cable in 2 stages, and cut and strip fiber optic cables made of plastic or glass and even with Kevlar reinforced fibers. It’s so flexible that it can precisely strip and slit 2 and 3 parallel conductor wires. With special setups, it can do an offset strip on 2 parallel conductor wires. Wire lengths are not a problem it will measure and cut lengths up to 99,999,99 inches, basically a mile and a half. Download the Eubanks Engineering AirStrip 2700 specifications for more detailed information. New Customers: Click here for information on ordering blades and blocks. Existing Customers: Click here for information on order blades. Existing Customers: Click here for information on order blocks.Speed

The 2700 cuts and strips both ends of the wire or cable in a single cycle and does this at blinding speeds of up to 10,300 pieces per hour. The 2700’s production screen can display the estimated pieces per hour being produced at the current feed speed. The production screen also displays an estimated time of completion. Because of its versatility and speed, the AirStrip 2700 is our most popular pneumatic stripper.User Friendly Programming

The 2700 is microprocessor-controlled, highly reliable, and easy to operate. It stores up to 1,000 programs containing separate wire parameters. It has built-in wire marking controls for pairing a wire marker. From its console, the operator can select and run programs, and step the machine through a complete cycle. It can easily be converted from inch to metric measurements via the machine’s keyboard. It has self-diagnostics. It also has length correction compensating fields designed to fine-tune to the best exact length tolerance possible.High-Precision

Our pneumatic strippers use unique hand-machined precision die blades and blocks. The tooling setups will last years and deliver the best quality strip available. During the strip function, the custom blades butt up against one another cutting perfectly around the circumference of the conductor. During the pull to strip, the insulation is held perfectly by both the top and bottom strip blades for a perfect linear pull when stripping. The result is a perfect 180° square cut of the insulation without any damage to the conductor ideal for proper termination. We design and manufacture all our blades using our proprietary processes. These processes assure high-precision performance over a long service life. This is where Eubanks excels. We can design special tooling to cut, strip, and slit on parallel wires and offset stripping. Customers have learned to rely on our extensive strip-blade expertise as they adapt to new insulations and tough applications. -

Our 60" Machine Tables for wire processing feature 12 gauge steel; all welded machine tables have a 3000 lb capacity. A lower shelf accommodates a storage toolbox of choice. Each table has a height of 32 in and a depth of 24 in. The 24-in depth provides plenty of work space when changing tooling setups on your Eubanks stripper. Additional tables can be set side-by-side to accommodate all Eubanks systems and any additional desired work space. Steel tables can be grounded and secured to the floor and can also be made mobile by installing casters. To learn more please download the Machine Tables for Wire Processing product specifications.

Our 60" Machine Tables for wire processing feature 12 gauge steel; all welded machine tables have a 3000 lb capacity. A lower shelf accommodates a storage toolbox of choice. Each table has a height of 32 in and a depth of 24 in. The 24-in depth provides plenty of work space when changing tooling setups on your Eubanks stripper. Additional tables can be set side-by-side to accommodate all Eubanks systems and any additional desired work space. Steel tables can be grounded and secured to the floor and can also be made mobile by installing casters. To learn more please download the Machine Tables for Wire Processing product specifications. -

The 48-inch Short Wire Stacker is a pedestal-mounted, V-shaped trough for collecting short wires produced by an automatic stripper. A rubber wire stop in the trough can be adjusted quickly to handle different wire sizes. Models 3175-01 and 15401-02 have a 48 in (1219mm) trough. Sides of the troughs slope at a 45° angle for easy wire removal. The height is adjustable. Model 3175-01 Is designed to work with all Pneumatic Automatic Wire Strippers. It requires interface Kit No. 15490-03 Model 15401-02 Is designed to work with all AutoStrip electric programmable strippers. It requires interface Kits No. 13747-02 for Models 7600 and 8900. For model 4900 used Kit No. 15316-02. To learn more download the Eubanks Engineering Model 3175-01 and 15401-02 48-inch Short Wire Collector product specifications.

The 48-inch Short Wire Stacker is a pedestal-mounted, V-shaped trough for collecting short wires produced by an automatic stripper. A rubber wire stop in the trough can be adjusted quickly to handle different wire sizes. Models 3175-01 and 15401-02 have a 48 in (1219mm) trough. Sides of the troughs slope at a 45° angle for easy wire removal. The height is adjustable. Model 3175-01 Is designed to work with all Pneumatic Automatic Wire Strippers. It requires interface Kit No. 15490-03 Model 15401-02 Is designed to work with all AutoStrip electric programmable strippers. It requires interface Kits No. 13747-02 for Models 7600 and 8900. For model 4900 used Kit No. 15316-02. To learn more download the Eubanks Engineering Model 3175-01 and 15401-02 48-inch Short Wire Collector product specifications. -

Our 48" Machine Tables for wire processing feature 12 gauge steel; all welded machine tables have a 3000 lb capacity. A lower shelf accommodates a storage toolbox of choice. Each table has a height of 32 in and a depth of 24 in. The 24-in depth provides plenty of work space when changing tooling setups on your Eubanks stripper. Additional tables can be set side-by-side to accommodate all Eubanks systems and any additional desired work space. Steel tables can be grounded and secured to the floor and can also be made mobile by installing casters. To learn more please download the Machine Tables for Wire Processing product specifications.

Our 48" Machine Tables for wire processing feature 12 gauge steel; all welded machine tables have a 3000 lb capacity. A lower shelf accommodates a storage toolbox of choice. Each table has a height of 32 in and a depth of 24 in. The 24-in depth provides plenty of work space when changing tooling setups on your Eubanks stripper. Additional tables can be set side-by-side to accommodate all Eubanks systems and any additional desired work space. Steel tables can be grounded and secured to the floor and can also be made mobile by installing casters. To learn more please download the Machine Tables for Wire Processing product specifications. -

Our 36" Machine Tables for wire processing feature 12 gauge steel; all welded machine tables have a 3000 lb capacity. A lower shelf accommodates a storage toolbox of choice. Each table has a height of 32 in and a depth of 24 in. The 24-in depth provides plenty of work space when changing tooling setups on your Eubanks stripper. Additional tables can be set side-by-side to accommodate all Eubanks systems and any additional desired work space. Steel tables can be grounded and secured to the floor and can also be made mobile by installing casters. To learn more please download the Machine Tables for Wire Processing product specifications.

Our 36" Machine Tables for wire processing feature 12 gauge steel; all welded machine tables have a 3000 lb capacity. A lower shelf accommodates a storage toolbox of choice. Each table has a height of 32 in and a depth of 24 in. The 24-in depth provides plenty of work space when changing tooling setups on your Eubanks stripper. Additional tables can be set side-by-side to accommodate all Eubanks systems and any additional desired work space. Steel tables can be grounded and secured to the floor and can also be made mobile by installing casters. To learn more please download the Machine Tables for Wire Processing product specifications.