-

WirePro Software for Windows enables you to create large wire list files with virtually no limit on the amount of data stored. It provides direct, error-free downloading of wire list data from the PC to the AutoTab and to the AutoStrip. WirePro provides instant recall of previously run wire lists, and it prompts the operator to select the correct wire type, color, and gauge when changing wire spools. With its wire meter, the WirePro software also records the amount of wire usage that has been processed. Wire list files can be sorted either by wire gauge, stock or part number. The WirePro software is easy to understand and operate. It uses simple dialog boxes to enable the operator to select a wire file, download it to the AutoStrip and the AutoTab, and start production. The operator can pause production at any time. When a wire-fault has been detected by the optional Spark Tester, the monitor displays a fault-recovery dialog box which provides the operator with various options for resuming production.

WirePro Software for Windows enables you to create large wire list files with virtually no limit on the amount of data stored. It provides direct, error-free downloading of wire list data from the PC to the AutoTab and to the AutoStrip. WirePro provides instant recall of previously run wire lists, and it prompts the operator to select the correct wire type, color, and gauge when changing wire spools. With its wire meter, the WirePro software also records the amount of wire usage that has been processed. Wire list files can be sorted either by wire gauge, stock or part number. The WirePro software is easy to understand and operate. It uses simple dialog boxes to enable the operator to select a wire file, download it to the AutoStrip and the AutoTab, and start production. The operator can pause production at any time. When a wire-fault has been detected by the optional Spark Tester, the monitor displays a fault-recovery dialog box which provides the operator with various options for resuming production. -

This is an optional Windows software package that enables you to use a personal computer to control the AutoStrip. WireManager software handles both the task of wire list data processing and the task of controlling the production of cut and stripped wires by downloading operating instructions to the AutoStrip. It runs under the Windows 10 operating system. The wire list data processing functions allow you to create large lists of wires, called harness files, by entering information for each wire such as length, gauge, strip length, wire type, etc. Coupled with the data for each wire are user programmable machine operating parameters such as wire feed speed, wire acceleration/deceleration, etc. The wires in each harness file can be sorted by wire gauge, wire stock number or part number. The user can create new harness files, load and edit previous harness files, search for a particular wire and print the files. Wire Manager Software enables you to use a PC to control the operation of your AutoStripYou start the wire production task by loading a harness file from the computer's disk. The WireManager software automatically downloads the data for each wire to the AutoStrip and instructs the AutoStrip to run each wire. The user can specify the order in which wires are produced and inhibit the production of selected wires. The WireManager software will prompt the operator when a different wire type must be loaded or when the characters on a manual wire marker need to be changed. The WireManager software can also be programmed to automatically interrupt production for certain conditions, such as the next wire or a wire with a user-set "pause-flag" WireManager also includes a feature called "Wire Meter". When enabled, the Wire Meter maintains a file that lists the amount of each type of wire that was used for the last job and a cumulative total of wire that has been used. WireManager software enables you to store virtually an unlimited number of harness files. It increases your productivity by minimizing repetitive data entry and reducing the possibility of operator error. Windows is a registered trademark of Microsoft Corp.

This is an optional Windows software package that enables you to use a personal computer to control the AutoStrip. WireManager software handles both the task of wire list data processing and the task of controlling the production of cut and stripped wires by downloading operating instructions to the AutoStrip. It runs under the Windows 10 operating system. The wire list data processing functions allow you to create large lists of wires, called harness files, by entering information for each wire such as length, gauge, strip length, wire type, etc. Coupled with the data for each wire are user programmable machine operating parameters such as wire feed speed, wire acceleration/deceleration, etc. The wires in each harness file can be sorted by wire gauge, wire stock number or part number. The user can create new harness files, load and edit previous harness files, search for a particular wire and print the files. Wire Manager Software enables you to use a PC to control the operation of your AutoStripYou start the wire production task by loading a harness file from the computer's disk. The WireManager software automatically downloads the data for each wire to the AutoStrip and instructs the AutoStrip to run each wire. The user can specify the order in which wires are produced and inhibit the production of selected wires. The WireManager software will prompt the operator when a different wire type must be loaded or when the characters on a manual wire marker need to be changed. The WireManager software can also be programmed to automatically interrupt production for certain conditions, such as the next wire or a wire with a user-set "pause-flag" WireManager also includes a feature called "Wire Meter". When enabled, the Wire Meter maintains a file that lists the amount of each type of wire that was used for the last job and a cumulative total of wire that has been used. WireManager software enables you to store virtually an unlimited number of harness files. It increases your productivity by minimizing repetitive data entry and reducing the possibility of operator error. Windows is a registered trademark of Microsoft Corp. -

The Eubanks AutoTab Wire Marking System comprises a series of computer-controlled machines whose printing discs are set automatically, along with wire length, batch count, distance between marks, air pressure, dwell time, wire drive speed, and acceleration and deceleration rates. A monitor displays all computer-controlled functions, which may be changed from the keyboard or from a host computer. One of these, the Model 77200 AutoTab, operates in line with an AutoStrip Automatic Wire Stripper. The Model 77200 AutoTab is a fully programmable hot stamp wire marker that operates in line with the AutoStrip. It links production planning software and wire processing to provide you with completely automatic marking, cutting and stripping. The Model 77200 selects marking characters quickly and accurately and places marks along the wire exactly where you want them. Printing discs are set automatically, along with stamp pressure, dwell time, distance from the end of the wire to the first mark and distance between marks. Temperature is set manually. The Model 77200 AutoTab includes Eubanks' WirePro for Windows software, which enables you to create large wire list files on your PC and provides direct, error-free downloading of wire list data from the PC to the AutoStrip and the 77200. It provides instant recall of previously run wire lists and it prompts the operator to select the correct wire type, color and gauge when changing wires. The WirePro for Windows software is easy to understand and was designed so that non-technical personnel can operate the 77200. It uses simple dialog boxes to enable the operator to select a wire file, download it to the AutoStrip and the AutoTab and start production. The operator can interrupt production at any time. When a wire-fault has been detected by the splice detector or the optional 64055 Spark Tester, the PC's monitor displays a fault-recovery dialog box that provides the operator with various options for resuming production.

The Eubanks AutoTab Wire Marking System comprises a series of computer-controlled machines whose printing discs are set automatically, along with wire length, batch count, distance between marks, air pressure, dwell time, wire drive speed, and acceleration and deceleration rates. A monitor displays all computer-controlled functions, which may be changed from the keyboard or from a host computer. One of these, the Model 77200 AutoTab, operates in line with an AutoStrip Automatic Wire Stripper. The Model 77200 AutoTab is a fully programmable hot stamp wire marker that operates in line with the AutoStrip. It links production planning software and wire processing to provide you with completely automatic marking, cutting and stripping. The Model 77200 selects marking characters quickly and accurately and places marks along the wire exactly where you want them. Printing discs are set automatically, along with stamp pressure, dwell time, distance from the end of the wire to the first mark and distance between marks. Temperature is set manually. The Model 77200 AutoTab includes Eubanks' WirePro for Windows software, which enables you to create large wire list files on your PC and provides direct, error-free downloading of wire list data from the PC to the AutoStrip and the 77200. It provides instant recall of previously run wire lists and it prompts the operator to select the correct wire type, color and gauge when changing wires. The WirePro for Windows software is easy to understand and was designed so that non-technical personnel can operate the 77200. It uses simple dialog boxes to enable the operator to select a wire file, download it to the AutoStrip and the AutoTab and start production. The operator can interrupt production at any time. When a wire-fault has been detected by the splice detector or the optional 64055 Spark Tester, the PC's monitor displays a fault-recovery dialog box that provides the operator with various options for resuming production. -

The Eubanks AutoTab Wire Marking System comprises a series of computer-controlled machines whose printing discs are set automatically, along with wire length, batch count, distance between marks, air pressure, dwell time, wire drive speed, and acceleration and deceleration rates. A monitor displays all computer-controlled functions, which may be changed from the keyboard or from a host computer. One of these, the Model 77200 AutoTab, operates in line with an AutoStrip Automatic Wire Stripper. The Model 77200 AutoTab is a fully programmable hot stamp wire marker that operates in line with the AutoStrip. It links production planning software and wire processing to provide you with completely automatic marking, cutting and stripping. The Model 77200 selects marking characters quickly and accurately and places marks along the wire exactly where you want them. Printing discs are set automatically, along with stamp pressure, dwell time, distance from the end of the wire to the first mark and distance between marks. Temperature is set manually. The Model 77200 AutoTab includes Eubanks' WirePro for Windows software, which enables you to create large wire list files on your PC and provides direct, error-free downloading of wire list data from the PC to the AutoStrip and the 77200. It provides instant recall of previously run wire lists and it prompts the operator to select the correct wire type, color and gauge when changing wires. The WirePro for Windows software is easy to understand and was designed so that non-technical personnel can operate the 77200. It uses simple dialog boxes to enable the operator to select a wire file, download it to the AutoStrip and the AutoTab and start production. The operator can interrupt production at any time. When a wire-fault has been detected by the splice detector or the optional 64055 Spark Tester, the PC's monitor displays a fault-recovery dialog box that provides the operator with various options for resuming production.

The Eubanks AutoTab Wire Marking System comprises a series of computer-controlled machines whose printing discs are set automatically, along with wire length, batch count, distance between marks, air pressure, dwell time, wire drive speed, and acceleration and deceleration rates. A monitor displays all computer-controlled functions, which may be changed from the keyboard or from a host computer. One of these, the Model 77200 AutoTab, operates in line with an AutoStrip Automatic Wire Stripper. The Model 77200 AutoTab is a fully programmable hot stamp wire marker that operates in line with the AutoStrip. It links production planning software and wire processing to provide you with completely automatic marking, cutting and stripping. The Model 77200 selects marking characters quickly and accurately and places marks along the wire exactly where you want them. Printing discs are set automatically, along with stamp pressure, dwell time, distance from the end of the wire to the first mark and distance between marks. Temperature is set manually. The Model 77200 AutoTab includes Eubanks' WirePro for Windows software, which enables you to create large wire list files on your PC and provides direct, error-free downloading of wire list data from the PC to the AutoStrip and the 77200. It provides instant recall of previously run wire lists and it prompts the operator to select the correct wire type, color and gauge when changing wires. The WirePro for Windows software is easy to understand and was designed so that non-technical personnel can operate the 77200. It uses simple dialog boxes to enable the operator to select a wire file, download it to the AutoStrip and the AutoTab and start production. The operator can interrupt production at any time. When a wire-fault has been detected by the splice detector or the optional 64055 Spark Tester, the PC's monitor displays a fault-recovery dialog box that provides the operator with various options for resuming production. -

The 6815-07 Flat Cable Prefeed is designed exclusively for the Eubanks Model 4600 Cutter. It will handle Ribbon cable, Shrink Tubing, Nylon braids, Copper braids, Thin Flat Copper, or any other soft flat material that is rolled in a spool. The 6815-07 can support on its built-in arm a spool or reel weighing up to 60 Lbs (54kg). Download the Eubanks Engineering model 6815-07 Flat Cable Prefeed specifications for more detailed information.

The 6815-07 Flat Cable Prefeed is designed exclusively for the Eubanks Model 4600 Cutter. It will handle Ribbon cable, Shrink Tubing, Nylon braids, Copper braids, Thin Flat Copper, or any other soft flat material that is rolled in a spool. The 6815-07 can support on its built-in arm a spool or reel weighing up to 60 Lbs (54kg). Download the Eubanks Engineering model 6815-07 Flat Cable Prefeed specifications for more detailed information.Safety

The 6815-07 is designed as a stand-alone prefeed and can be used with any make of wire processing machine. When used with Eubanks 4600-03 Cutter, both the prefeed and the wire processor form an integrated system. This provides great safety as both prefeed and 4600 will shut down in the event of a wire jam or entanglement at the prefeed end due to poorly wound spools or reels.Practical

Once the proper exit pulley height is set, there are no tools required to operate the 6880-03. Using the manual toggle switch to load and unload wire will help to safely speed up spool changes. Using the variable speed control knob, you can achieve maximum synchronization with the wire processor. A 6880-05 will help increase accuracy in wire lengths and will help relieve any stresses to the materials. -

Protection

Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy reels. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6880-05 Prefeed helps protect and prolong the service life of your wire stripper as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6880-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6880-05 can accommodate delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible stranded wires. The 6880-05 can also support on its side stand a spool or reel weighing up to 120 lbs (54kg). Additional modification kits for working with 2/0 wire or flat cable are available. Download the Eubanks Engineering model 6880-05 Heavy-Duty Belt Drive Demand Prefeed specifications for more detailed information.Safety

The 6880-05 is designed as a stand-alone prefeed and can work with any make or brand of wire processing machines. When paired with a Eubanks wire processing machine, both the prefeed and the wire processor form an integrated system. This provides safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement.Practical

Once the exit pulley height is set, you can quickly load the wire onto the Prefeed’s wire drive by using the manual toggle switch. After threading the wire through the lower buffer pulley, and exit pulley, use the variable speed control knob to achieve maximum synchronization with the wire processor.Speed

The 6880-05 will boost production as it will allow you to program your wire processor at a faster speed. It will help increase accuracy in wire lengths and will help relieve any stress or deformation to the wire. -

For Bare Steel or Copper Wire

Robust

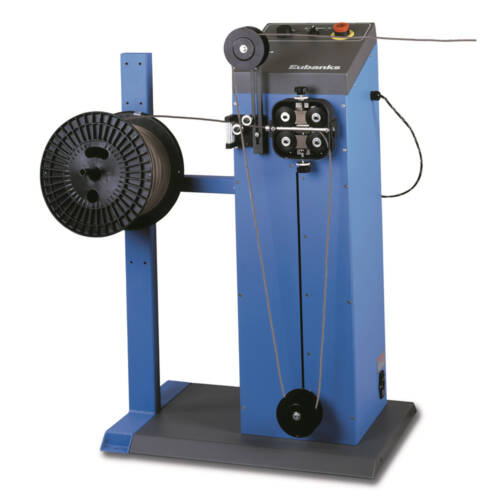

Bare copper wire or bare steel rope can slice the belts of a belt drive prefeed fairly quickly. The Model 6880-03 is designed for such applications. The 6880-03 is equipped with steel rollers that will grip any bare metal wire with no problem. Eubanks offers a variety of feed rollers with different contact surfaces for the 6880-03. There are rollers and guide tubes for accommodating delicate 30 AWG (.06mm²) bare copper wire and rollers for up to .250 in (6.3 mm) O.D. flexible bare steel rope. The 6880-03 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2 AWG (33.6mm²) flexible stranded wires. It can accommodate up to .250 in (6.3mm) flexible steel rope. The 6880-03 can support on its built-in spool stand a spool or reel weighing up to 120 lbs (54kg) or two small spools. Download the Eubanks Engineering model 6880-03 Heavy Duty Demand Prefeed specifications for more detailed information.Safety

The 6880-03 is designed as a stand-alone prefeed and can be used with any make of wire processing machine. When used with Eubanks wire processing machines, both the prefeed and the wire processor form an integrated system. This provides great safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement due to poorly wound spools or reels at the prefeed end.Practical

Once the proper exit pulley height is set, there are no tools required to operate the 6880-03. Using the manual toggle switch to load and unload wire will help to safely speed up spool changes. Using the variable speed control knob you can achieve maximum synchronization with the wire processor.Speed

A 6880-03 will boost production as it will allow you to set your wire processor to a faster speed. It will help increase accuracy in wire lengths and will help relieve any stresses to the wire. -

This Collector Tube is used to collect short wire lengths. It includes a 36 in (914mm) length of 2 in (51mm) diameter plastic tubing and two plastic end caps along with hardware for mounting the tubing on the side of a wire stripper or marker. The tubing may be cut to the desired length with scissors. Additional lengths of tubing may be ordered as Part No. 6933. The caps are supplied in pairs as Part No. 6934. The tubes with caps on each end provide a convenient way to store cut and stripped wire. To learn more download the Eubanks Engineering Model 6480 Collector Tube product specifications.

This Collector Tube is used to collect short wire lengths. It includes a 36 in (914mm) length of 2 in (51mm) diameter plastic tubing and two plastic end caps along with hardware for mounting the tubing on the side of a wire stripper or marker. The tubing may be cut to the desired length with scissors. Additional lengths of tubing may be ordered as Part No. 6933. The caps are supplied in pairs as Part No. 6934. The tubes with caps on each end provide a convenient way to store cut and stripped wire. To learn more download the Eubanks Engineering Model 6480 Collector Tube product specifications. -

The Eubanks 6835 Heavy-Duty Reel Stand is a simple and economical solution for dealing with large spools or reels. There is no lifting required when dealing with large spools. To mount reels, just roll them onto the built-in platforms, insert the shaft through the reel, set the adjustable shaft arm support then push off until it locks in place. The reel is dereeled tangentially to prevent line twists, which often occur in axial dereeling. Unlike popular floor rollers which depend on good solid spool flanges, the 6835 works the same with wooden spools that arrive with broken flanges. The 6835 will telescope out to accommodate a 22” wide reel. The maximum capacity is a 32” Diameter, 300 lb reel. The 6835 small footprint helps conserve valuable shop floor space. To learn more download the Eubanks Engineering Model 6835 Heavy-Duty Reel Stand product specifications.

The Eubanks 6835 Heavy-Duty Reel Stand is a simple and economical solution for dealing with large spools or reels. There is no lifting required when dealing with large spools. To mount reels, just roll them onto the built-in platforms, insert the shaft through the reel, set the adjustable shaft arm support then push off until it locks in place. The reel is dereeled tangentially to prevent line twists, which often occur in axial dereeling. Unlike popular floor rollers which depend on good solid spool flanges, the 6835 works the same with wooden spools that arrive with broken flanges. The 6835 will telescope out to accommodate a 22” wide reel. The maximum capacity is a 32” Diameter, 300 lb reel. The 6835 small footprint helps conserve valuable shop floor space. To learn more download the Eubanks Engineering Model 6835 Heavy-Duty Reel Stand product specifications. -

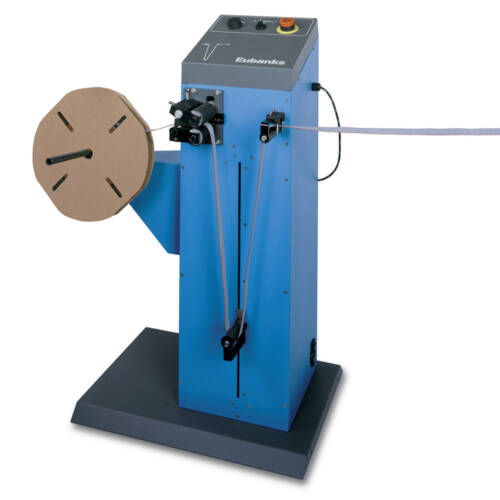

Protection Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy spools. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6815-05 Prefeed helps protect and prolong the service life of your wire processor as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6815-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6815-05 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible thin stranded wires. The 6815-05 can also support on its sidearm a spool or reel weighing up to 60 lbs (27kg). Download the Eubanks Engineering model 6815-05 Demand Prefeed specifications for more detailed information.

Protection Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy spools. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6815-05 Prefeed helps protect and prolong the service life of your wire processor as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6815-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6815-05 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible thin stranded wires. The 6815-05 can also support on its sidearm a spool or reel weighing up to 60 lbs (27kg). Download the Eubanks Engineering model 6815-05 Demand Prefeed specifications for more detailed information.Safety

The 6815-05 is designed as a stand-alone prefeed and can work with any make or brand of wire processing machines. When paired with a Eubanks wire processing machine, both the prefeed and the wire processor form an integrated system. This provides safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement.Practical

Once the exit pulley height is set, you can quickly load the wire onto the Prefeed’s wire drive by using the manual toggle switch. After threading the wire through the lower buffer pulley, and exit pulley, use the variable speed control knob to achieve maximum synchronization with the wire processor.Speed

The 6815-05 will boost production as it will allow you to program your wire processor at a faster speed. It will help increase wire length accuracy and will help relieve any stress or deformation to the wire. -

This machine does not have feed rolls to drive the wire. Wire is pulled through the machine manually or by an automatic wire stripper equipped with marker controls. It may be used with a Eubanks Automatic Wire Stripper equipped with marker controls for either end-marking or continuous marking at set intervals. An AutoStrip machine, when used with a Model 67200, provides the same control of mark placement as the AutoTab Wire Markers. The marking discs may be separated into two groups when the machine is used for end-marking. When used for end-mark- with a Eubanks AutoStrip, Model 2700 IV, or -V, or Model 1000-II, -III, or -IV Automatic Wire Stripper, the marker need not be repositioned when wire lengths are changed. When used with an earlier model Eubanks wire stripper for end-marking, the marker must be repositioned when wire lengths are changed. A traveling rack and dolly is available for this purpose. In the semi automatic mode, the operator pulls the wire or tubing through by hand and presses a foot switch to operate the Model 67200.

This machine does not have feed rolls to drive the wire. Wire is pulled through the machine manually or by an automatic wire stripper equipped with marker controls. It may be used with a Eubanks Automatic Wire Stripper equipped with marker controls for either end-marking or continuous marking at set intervals. An AutoStrip machine, when used with a Model 67200, provides the same control of mark placement as the AutoTab Wire Markers. The marking discs may be separated into two groups when the machine is used for end-marking. When used for end-mark- with a Eubanks AutoStrip, Model 2700 IV, or -V, or Model 1000-II, -III, or -IV Automatic Wire Stripper, the marker need not be repositioned when wire lengths are changed. When used with an earlier model Eubanks wire stripper for end-marking, the marker must be repositioned when wire lengths are changed. A traveling rack and dolly is available for this purpose. In the semi automatic mode, the operator pulls the wire or tubing through by hand and presses a foot switch to operate the Model 67200.