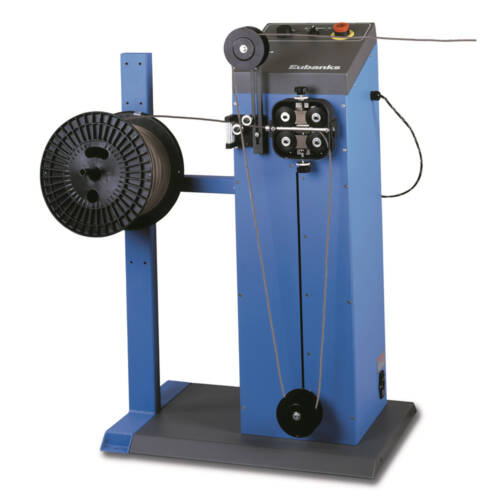

The Eubanks Series 6800 Prefeeds cover a broad range of production applications. They range from the basic Model 6815-05/06 belt drive to Heavy Duty models like the 6880-05/06 belt drive and the flat cable prefeed. Each offers quick response, automatic speed control, high torque, and dependability.

The belt drive models cover wire sizes ranging from 32 AWG to 2/00 AWG.

These prefeeds may be used with any make of wire processing machine. When used with a Eubanks machine, the prefeed, and the wire processor form an integrated system. Both the prefeed and the wire processor will shut down in the event of a jam or tangle at the prefeed end.

By delivering wire to the processor as required, the prefeed contributes to optimum wire-length accuracy and the longevity of the processor’s drive mechanisms.

A heavy-duty 1/2 hp motor provides ample power to rotate maximum-weight reels or pull wire from a barrel. A manual jog switch makes for easy loading and unloading of wire. A provision for mounting two reels makes it possible to speed up wire changeover.

-

Protection Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy spools. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6815-05 Prefeed helps protect and prolong the service life of your wire processor as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6815-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6815-05 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible thin stranded wires. The 6815-05 can also support on its sidearm a spool or reel weighing up to 60 lbs (27kg). Download the Eubanks Engineering model 6815-05 Demand Prefeed specifications for more detailed information.

Protection Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy spools. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6815-05 Prefeed helps protect and prolong the service life of your wire processor as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6815-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6815-05 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible thin stranded wires. The 6815-05 can also support on its sidearm a spool or reel weighing up to 60 lbs (27kg). Download the Eubanks Engineering model 6815-05 Demand Prefeed specifications for more detailed information. -

For Bare Steel or Copper Wire

Robust

Bare copper wire or bare steel rope can slice the belts of a belt drive prefeed fairly quickly. The Model 6880-03 is designed for such applications. The 6880-03 is equipped with steel rollers that will grip any bare metal wire with no problem. Eubanks offers a variety of feed rollers with different contact surfaces for the 6880-03. There are rollers and guide tubes for accommodating delicate 30 AWG (.06mm²) bare copper wire and rollers for up to .250 in (6.3 mm) O.D. flexible bare steel rope. The 6880-03 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2 AWG (33.6mm²) flexible stranded wires. It can accommodate up to .250 in (6.3mm) flexible steel rope. The 6880-03 can support on its built-in spool stand a spool or reel weighing up to 120 lbs (54kg) or two small spools. Download the Eubanks Engineering model 6880-03 Heavy Duty Demand Prefeed specifications for more detailed information.Safety

The 6880-03 is designed as a stand-alone prefeed and can be used with any make of wire processing machine. When used with Eubanks wire processing machines, both the prefeed and the wire processor form an integrated system. This provides great safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement due to poorly wound spools or reels at the prefeed end.Practical

Once the proper exit pulley height is set, there are no tools required to operate the 6880-03. Using the manual toggle switch to load and unload wire will help to safely speed up spool changes. Using the variable speed control knob you can achieve maximum synchronization with the wire processor.Speed

A 6880-03 will boost production as it will allow you to set your wire processor to a faster speed. It will help increase accuracy in wire lengths and will help relieve any stresses to the wire. -

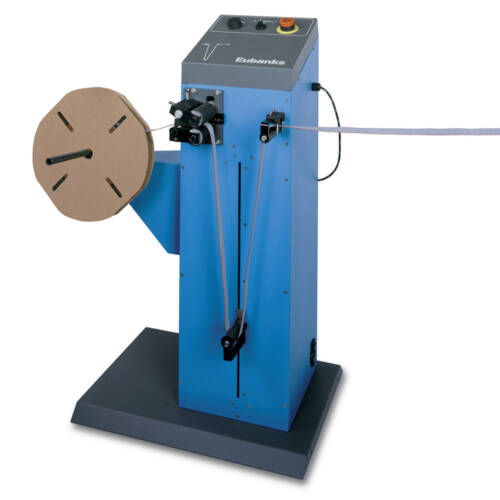

Protection

Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy reels. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6880-05 Prefeed helps protect and prolong the service life of your wire stripper as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6880-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6880-05 can accommodate delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible stranded wires. The 6880-05 can also support on its side stand a spool or reel weighing up to 120 lbs (54kg). Additional modification kits for working with 2/0 wire or flat cable are available. Download the Eubanks Engineering model 6880-05 Heavy-Duty Belt Drive Demand Prefeed specifications for more detailed information.Safety

The 6880-05 is designed as a stand-alone prefeed and can work with any make or brand of wire processing machines. When paired with a Eubanks wire processing machine, both the prefeed and the wire processor form an integrated system. This provides safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement.Practical

Once the exit pulley height is set, you can quickly load the wire onto the Prefeed’s wire drive by using the manual toggle switch. After threading the wire through the lower buffer pulley, and exit pulley, use the variable speed control knob to achieve maximum synchronization with the wire processor.Speed

The 6880-05 will boost production as it will allow you to program your wire processor at a faster speed. It will help increase accuracy in wire lengths and will help relieve any stress or deformation to the wire. -

The 6815-07 Flat Cable Prefeed is designed exclusively for the Eubanks Model 4600 Cutter. It will handle Ribbon cable, Shrink Tubing, Nylon braids, Copper braids, Thin Flat Copper, or any other soft flat material that is rolled in a spool. The 6815-07 can support on its built-in arm a spool or reel weighing up to 60 Lbs (54kg). Download the Eubanks Engineering model 6815-07 Flat Cable Prefeed specifications for more detailed information.

The 6815-07 Flat Cable Prefeed is designed exclusively for the Eubanks Model 4600 Cutter. It will handle Ribbon cable, Shrink Tubing, Nylon braids, Copper braids, Thin Flat Copper, or any other soft flat material that is rolled in a spool. The 6815-07 can support on its built-in arm a spool or reel weighing up to 60 Lbs (54kg). Download the Eubanks Engineering model 6815-07 Flat Cable Prefeed specifications for more detailed information.Safety

The 6815-07 is designed as a stand-alone prefeed and can be used with any make of wire processing machine. When used with Eubanks 4600-03 Cutter, both the prefeed and the wire processor form an integrated system. This provides great safety as both prefeed and 4600 will shut down in the event of a wire jam or entanglement at the prefeed end due to poorly wound spools or reels.Practical

Once the proper exit pulley height is set, there are no tools required to operate the 6880-03. Using the manual toggle switch to load and unload wire will help to safely speed up spool changes. Using the variable speed control knob, you can achieve maximum synchronization with the wire processor. A 6880-05 will help increase accuracy in wire lengths and will help relieve any stresses to the materials.