-

Managing long wires as they come out of the wire stripper is extremely hard and nearly impossible. Normally, a great amount of time is spent trying to detangle and hand coil a wire for storage or the next wire process. Eubanks Coiling Pans provide a fast and convenient way to collect wire as it comes out of the wire stripper. The top lip of the pan keeps wire in place while still allowing easy access for removal of the coiled wire. Our standard coiling pan is manufactured from spun aluminum and is 12 in (308mm) in diameter and 3 in (77mm) deep. Other sizes are available on special order. To learn more please download the Model 16100 Tracking Motorized Coiling Pan product specifications.

Managing long wires as they come out of the wire stripper is extremely hard and nearly impossible. Normally, a great amount of time is spent trying to detangle and hand coil a wire for storage or the next wire process. Eubanks Coiling Pans provide a fast and convenient way to collect wire as it comes out of the wire stripper. The top lip of the pan keeps wire in place while still allowing easy access for removal of the coiled wire. Our standard coiling pan is manufactured from spun aluminum and is 12 in (308mm) in diameter and 3 in (77mm) deep. Other sizes are available on special order. To learn more please download the Model 16100 Tracking Motorized Coiling Pan product specifications. -

Managing long wires as they come out of the wire stripper is extremely hard and nearly impossible. Normally, a great amount of time is spent trying to detangle and hand coil a wire for storage or the next wire process. Eubanks Coiling Pans provide a fast and convenient way to collect wire as it comes out of the wire stripper. The top lip of the pan keeps wire in place while still allowing easy access for removal of the coiled wire. Our standard coiling pan is manufactured from spun aluminum and is 12 in (308mm) in diameter and 3 in (77mm) deep. Other sizes are available on special order. To learn more please download the Model 16110 Tracking Motorized Coiling Pan product specifications.

Managing long wires as they come out of the wire stripper is extremely hard and nearly impossible. Normally, a great amount of time is spent trying to detangle and hand coil a wire for storage or the next wire process. Eubanks Coiling Pans provide a fast and convenient way to collect wire as it comes out of the wire stripper. The top lip of the pan keeps wire in place while still allowing easy access for removal of the coiled wire. Our standard coiling pan is manufactured from spun aluminum and is 12 in (308mm) in diameter and 3 in (77mm) deep. Other sizes are available on special order. To learn more please download the Model 16110 Tracking Motorized Coiling Pan product specifications. -

The Model 1722 Non-Motorized Coiling Pan and Pedestal is an inexpensive and convenient accessory for collecting the wire as it comes out of a wire stripper or marker. It includes our standard 12-inch (308mm.) diameter pan mounted on a ball bearing so that it turns freely As the wire is ejected from the wire processor, it is guided into the pan and causes the pan to rotate and coil the wire. The Model 1722 is free standing and includes its own pedestal.

The Model 1722 Non-Motorized Coiling Pan and Pedestal is an inexpensive and convenient accessory for collecting the wire as it comes out of a wire stripper or marker. It includes our standard 12-inch (308mm.) diameter pan mounted on a ball bearing so that it turns freely As the wire is ejected from the wire processor, it is guided into the pan and causes the pan to rotate and coil the wire. The Model 1722 is free standing and includes its own pedestal. -

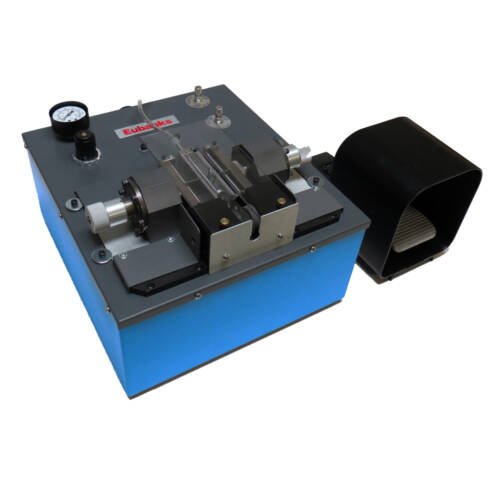

Versatile Precision Semi-Automatic Bench Stripper

The model 3751 wire and cable stripper is fast versatile and easy to use. The 3751 is ideal from simple low volume applications to relieve operators from hand stripping and up to no nick or scrape precision stripping. The 3751 can quickly strip accurately single conductor wires and many other cable types. It excels in reworking cables to the correct strip length and stripping the end of a pre-molded multi-conductor power cable. Using the special multi-conductor strip package the 3751 can strip the inner conductors of a multi-conductor cable in a single pass. The 3751 is 100% pneumatic and very powerful. It can strip the plastic coating off pre-cut to length steel rope and also strip up to 2 AWG (33.6mm²) battery cable. There is a wide variety of tooling for most manufacturing cables that can be adapted to this small bench-stripper. Download the Eubanks Engineering 3751 Wire & Cable Stripper specifications for more detailed information.User Friendly

There is no learning curve required with the 3751. The machine is activated by stepping on an air operated footswitch which comfortably frees the operator’s hands. To strip a wire, simply insert the end to be stripped on the slot located in front of the 3751 or drop from the opening above. Once the wire is in position, step on the foot switch and that is all. The 3751 will automatically clamp the wire as the strip blades cut the insulation and then will fully remove it or leave it at the end semi-stripped. Blade change is done in seconds. To change the blades, simply turn the air off, remove the top plastic guard, remove the two blade pins and change the blades. To change the strip length, simply loosen the screw on the clamp that holds the wire stop, reposition the wire stop to the desired length and retighten the clamp screw.High-Precision

Our pneumatic strippers use unique hand machined precision die blades and blocks. These setups last years, and deliver the best quality strip available. During the strip function, the blades butt-up against one another cutting perfectly around the circumference of the conductor. During the pull to strip, the insulation is held by perfectly by both top and bottom strip blades giving a perfect linear pull when stripping. The end result is a perfect 180° square cut of the insulation without any damage to the conductor. We design and manufacture all our own blades using our proprietary processes. These processes assure high-precision performance over a long service life. This is where Eubanks clearly excels. Customers have learned to rely on our extensive strip-blade expertise as they adapt to new insulations and tough applications. -

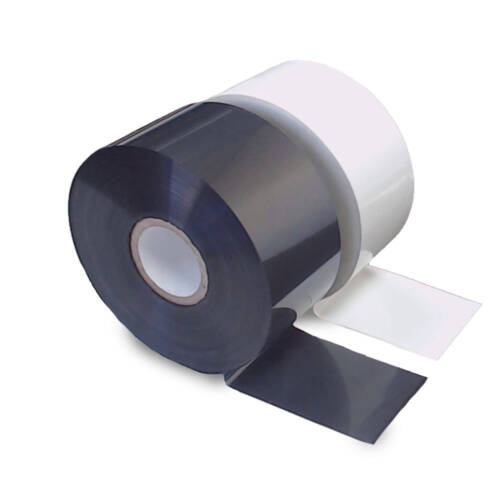

The Eubanks 4600 is a proven workhorse and one of the most versatile products Eubanks manufactures. The 4600 is one of the few machines that serve many industries such as Aerospace, Automotive, Medical, and Manufacturing. The 4600 can measure and cut most soft linear plastics or metals. It can cut hose tubing with a maximum diameter of .375” (9.5mm). It will also process flat materials such as shrink tubing or ribbon cable up to 3” (76.2mm) wide or when flatten. Equipped with optional carbide cutting blades the 4600 can also cut Kevlar reinforced Fiber Optic Cables. The 4600-03 is designed with a few robust moving parts, making it very reliable and durable. Blade and Drive Roller changes are easy and require minimal tools. Speed and Precision The 4600 can cut materials up to 23,200 pieces per hour of 1/8” (3.1mm) in length. The 4600 can also maintain a tolerance of ± .020” (.5mm). User-Friendly Programming The 4600 has no learning curve, simply insert the material between the two drive rollers and press the cut button to zero out. Enter a cut length and a batch quantity and press the go button. The watch as the 4600 does its work at blinding speeds. That is how simple it is to operate. The 4600 has a quick locking cam lever for raising the top drive roller for easy material insertion. Eubanks offers control panels in 6 different languages, English, Spanish, French, German, Swedish, and Italian. For more information please download Eubanks Engineering's Model 4600 Tubing and Flat-Cable Cutter product specifications.

The Eubanks 4600 is a proven workhorse and one of the most versatile products Eubanks manufactures. The 4600 is one of the few machines that serve many industries such as Aerospace, Automotive, Medical, and Manufacturing. The 4600 can measure and cut most soft linear plastics or metals. It can cut hose tubing with a maximum diameter of .375” (9.5mm). It will also process flat materials such as shrink tubing or ribbon cable up to 3” (76.2mm) wide or when flatten. Equipped with optional carbide cutting blades the 4600 can also cut Kevlar reinforced Fiber Optic Cables. The 4600-03 is designed with a few robust moving parts, making it very reliable and durable. Blade and Drive Roller changes are easy and require minimal tools. Speed and Precision The 4600 can cut materials up to 23,200 pieces per hour of 1/8” (3.1mm) in length. The 4600 can also maintain a tolerance of ± .020” (.5mm). User-Friendly Programming The 4600 has no learning curve, simply insert the material between the two drive rollers and press the cut button to zero out. Enter a cut length and a batch quantity and press the go button. The watch as the 4600 does its work at blinding speeds. That is how simple it is to operate. The 4600 has a quick locking cam lever for raising the top drive roller for easy material insertion. Eubanks offers control panels in 6 different languages, English, Spanish, French, German, Swedish, and Italian. For more information please download Eubanks Engineering's Model 4600 Tubing and Flat-Cable Cutter product specifications. -

This machine does not have feed rolls to drive the wire. Wire is pulled through the machine manually or by an automatic wire stripper equipped with marker controls. It may be used with a Eubanks Automatic Wire Stripper equipped with marker controls for either end-marking or continuous marking at set intervals. An AutoStrip machine, when used with a Model 67200, provides the same control of mark placement as the AutoTab Wire Markers. The marking discs may be separated into two groups when the machine is used for end-marking. When used for end-mark- with a Eubanks AutoStrip, Model 2700 IV, or -V, or Model 1000-II, -III, or -IV Automatic Wire Stripper, the marker need not be repositioned when wire lengths are changed. When used with an earlier model Eubanks wire stripper for end-marking, the marker must be repositioned when wire lengths are changed. A traveling rack and dolly is available for this purpose. In the semi automatic mode, the operator pulls the wire or tubing through by hand and presses a foot switch to operate the Model 67200.

This machine does not have feed rolls to drive the wire. Wire is pulled through the machine manually or by an automatic wire stripper equipped with marker controls. It may be used with a Eubanks Automatic Wire Stripper equipped with marker controls for either end-marking or continuous marking at set intervals. An AutoStrip machine, when used with a Model 67200, provides the same control of mark placement as the AutoTab Wire Markers. The marking discs may be separated into two groups when the machine is used for end-marking. When used for end-mark- with a Eubanks AutoStrip, Model 2700 IV, or -V, or Model 1000-II, -III, or -IV Automatic Wire Stripper, the marker need not be repositioned when wire lengths are changed. When used with an earlier model Eubanks wire stripper for end-marking, the marker must be repositioned when wire lengths are changed. A traveling rack and dolly is available for this purpose. In the semi automatic mode, the operator pulls the wire or tubing through by hand and presses a foot switch to operate the Model 67200. -

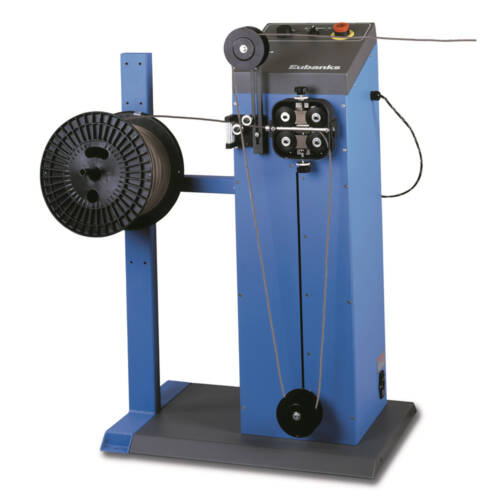

Protection Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy spools. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6815-05 Prefeed helps protect and prolong the service life of your wire processor as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6815-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6815-05 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible thin stranded wires. The 6815-05 can also support on its sidearm a spool or reel weighing up to 60 lbs (27kg). Download the Eubanks Engineering model 6815-05 Demand Prefeed specifications for more detailed information.

Protection Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy spools. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6815-05 Prefeed helps protect and prolong the service life of your wire processor as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6815-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6815-05 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible thin stranded wires. The 6815-05 can also support on its sidearm a spool or reel weighing up to 60 lbs (27kg). Download the Eubanks Engineering model 6815-05 Demand Prefeed specifications for more detailed information.Safety

The 6815-05 is designed as a stand-alone prefeed and can work with any make or brand of wire processing machines. When paired with a Eubanks wire processing machine, both the prefeed and the wire processor form an integrated system. This provides safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement.Practical

Once the exit pulley height is set, you can quickly load the wire onto the Prefeed’s wire drive by using the manual toggle switch. After threading the wire through the lower buffer pulley, and exit pulley, use the variable speed control knob to achieve maximum synchronization with the wire processor.Speed

The 6815-05 will boost production as it will allow you to program your wire processor at a faster speed. It will help increase wire length accuracy and will help relieve any stress or deformation to the wire. -

The Eubanks 6835 Heavy-Duty Reel Stand is a simple and economical solution for dealing with large spools or reels. There is no lifting required when dealing with large spools. To mount reels, just roll them onto the built-in platforms, insert the shaft through the reel, set the adjustable shaft arm support then push off until it locks in place. The reel is dereeled tangentially to prevent line twists, which often occur in axial dereeling. Unlike popular floor rollers which depend on good solid spool flanges, the 6835 works the same with wooden spools that arrive with broken flanges. The 6835 will telescope out to accommodate a 22” wide reel. The maximum capacity is a 32” Diameter, 300 lb reel. The 6835 small footprint helps conserve valuable shop floor space. To learn more download the Eubanks Engineering Model 6835 Heavy-Duty Reel Stand product specifications.

The Eubanks 6835 Heavy-Duty Reel Stand is a simple and economical solution for dealing with large spools or reels. There is no lifting required when dealing with large spools. To mount reels, just roll them onto the built-in platforms, insert the shaft through the reel, set the adjustable shaft arm support then push off until it locks in place. The reel is dereeled tangentially to prevent line twists, which often occur in axial dereeling. Unlike popular floor rollers which depend on good solid spool flanges, the 6835 works the same with wooden spools that arrive with broken flanges. The 6835 will telescope out to accommodate a 22” wide reel. The maximum capacity is a 32” Diameter, 300 lb reel. The 6835 small footprint helps conserve valuable shop floor space. To learn more download the Eubanks Engineering Model 6835 Heavy-Duty Reel Stand product specifications. -

This Collector Tube is used to collect short wire lengths. It includes a 36 in (914mm) length of 2 in (51mm) diameter plastic tubing and two plastic end caps along with hardware for mounting the tubing on the side of a wire stripper or marker. The tubing may be cut to the desired length with scissors. Additional lengths of tubing may be ordered as Part No. 6933. The caps are supplied in pairs as Part No. 6934. The tubes with caps on each end provide a convenient way to store cut and stripped wire. To learn more download the Eubanks Engineering Model 6480 Collector Tube product specifications.

This Collector Tube is used to collect short wire lengths. It includes a 36 in (914mm) length of 2 in (51mm) diameter plastic tubing and two plastic end caps along with hardware for mounting the tubing on the side of a wire stripper or marker. The tubing may be cut to the desired length with scissors. Additional lengths of tubing may be ordered as Part No. 6933. The caps are supplied in pairs as Part No. 6934. The tubes with caps on each end provide a convenient way to store cut and stripped wire. To learn more download the Eubanks Engineering Model 6480 Collector Tube product specifications. -

For Bare Steel or Copper Wire

Robust

Bare copper wire or bare steel rope can slice the belts of a belt drive prefeed fairly quickly. The Model 6880-03 is designed for such applications. The 6880-03 is equipped with steel rollers that will grip any bare metal wire with no problem. Eubanks offers a variety of feed rollers with different contact surfaces for the 6880-03. There are rollers and guide tubes for accommodating delicate 30 AWG (.06mm²) bare copper wire and rollers for up to .250 in (6.3 mm) O.D. flexible bare steel rope. The 6880-03 can accommodate from delicate 30 AWG (.06mm²) wire and up to 2 AWG (33.6mm²) flexible stranded wires. It can accommodate up to .250 in (6.3mm) flexible steel rope. The 6880-03 can support on its built-in spool stand a spool or reel weighing up to 120 lbs (54kg) or two small spools. Download the Eubanks Engineering model 6880-03 Heavy Duty Demand Prefeed specifications for more detailed information.Safety

The 6880-03 is designed as a stand-alone prefeed and can be used with any make of wire processing machine. When used with Eubanks wire processing machines, both the prefeed and the wire processor form an integrated system. This provides great safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement due to poorly wound spools or reels at the prefeed end.Practical

Once the proper exit pulley height is set, there are no tools required to operate the 6880-03. Using the manual toggle switch to load and unload wire will help to safely speed up spool changes. Using the variable speed control knob you can achieve maximum synchronization with the wire processor.Speed

A 6880-03 will boost production as it will allow you to set your wire processor to a faster speed. It will help increase accuracy in wire lengths and will help relieve any stresses to the wire. -

Protection

Wire Processors electric or pneumatic are engineered for cutting and stripping wires or cables. Wire Processors are not designed for pulling the wire off heavy reels. Pulling wire off heavy spools or reels can overstress and prematurely wear or damage the Wire Processor’s wire drive mechanisms. The model 6880-05 Prefeed helps protect and prolong the service life of your wire stripper as it absorbs the stresses that come from tugging and pulling wire, thus protecting your investment. The 6880-05 comes equipped with standard wire drive belts made of a unique Kevlar composition. The Green Kevlar belts have a long wear life and will not mark or damage the wire’s insulation. The 6880-05 can accommodate delicate 30 AWG (.06mm²) wire and up to 2/0 AWG (69mm²) flexible stranded wires. The 6880-05 can also support on its side stand a spool or reel weighing up to 120 lbs (54kg). Additional modification kits for working with 2/0 wire or flat cable are available. Download the Eubanks Engineering model 6880-05 Heavy-Duty Belt Drive Demand Prefeed specifications for more detailed information.Safety

The 6880-05 is designed as a stand-alone prefeed and can work with any make or brand of wire processing machines. When paired with a Eubanks wire processing machine, both the prefeed and the wire processor form an integrated system. This provides safety as both the prefeed and wire processor will shut down in the event of a wire jam or entanglement.Practical

Once the exit pulley height is set, you can quickly load the wire onto the Prefeed’s wire drive by using the manual toggle switch. After threading the wire through the lower buffer pulley, and exit pulley, use the variable speed control knob to achieve maximum synchronization with the wire processor.Speed

The 6880-05 will boost production as it will allow you to program your wire processor at a faster speed. It will help increase accuracy in wire lengths and will help relieve any stress or deformation to the wire.