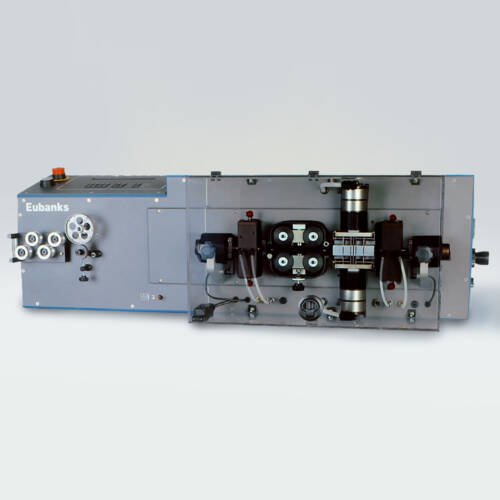

Small steel cables also known as steel rope are used for everything from automotive clutches and braking systems to electronic security devices in retail stores. The smallest of steel cables can cause stress and damage to most electric stripper’s parts, blades, and motors. Many dynamics happen to metals when cutting steel. There are micro explosions that generate heat and can cause metal strains, fatigue, warping, or damage. Some of these cables are case-hardened compounding the difficulty of cutting as they can shatter some carbide-cut blades. Eubanks has a solution with the 2745-06 and its proprietary special steel-cutting tooling. The tooling is designed to cut steel cables and withstand the dynamic stresses that happen when processing steel cables for prolonged periods. There is no worrying about burning up motors with the air-powered 2745-06. Equipped with the standard tooling, the 2745-06 can cut steel rope soft or case hardened up to a maximum O.D. of .187” (4.7mm).

Download the Eubanks Engineering Model 2745-06 specifications for more detailed information.

Speed

The 2745-06 cuts production screen can display the estimated pieces per hour being produced at the current feed speed. The production screen also displays an estimated time of completion. The heavy-duty 2745-06 is the perfect long-term solution for cutting difficult Steel Rope Cables.

User Friendly Programming

The 2745-06 is highly reliable and easy to operate. It stores up to 1,000 programs each containing separate cable profiles such as lengths, batch quantities, and delays. Also has built-in wire marking controls for pairing a wire marker if desired to mark numbers and letters on a plastic-coated steel rope. From its console, the operator can select and run programs, and step the machine through a complete cycle. It can easily be converted from inch to metric measurements via the machine’s keyboard. It also has length correction compensating fields designed to fine-tune to the best exact length tolerance possible.

High-Precision

Our pneumatic strippers use unique hand-machined precision die blades and blocks. These setups will last years and deliver the best quality strip available. During the strip function, the blades butt up against one another cutting perfectly around the circumference of the conductor. During the pull to strip, the insulation is held by both the top and bottom strip blades for a perfect linear pull as it strips. The result is a perfect 180° square cut on both the plastic insulation and steel cable without any damage to the conductor or blades while delivering perfect ends for termination.

We design and manufacture all our blades using our proprietary processes. These processes assure high-precision performance over a long service life. This is where Eubanks excels. We can design special tooling to cut, strip, and slit on parallel wires and offset stripping. Customers have learned to rely on our extensive strip-blade expertise as they adapt to new insulations and tough applications.